The first TIPROT variety - TIPROT 1

TIPROT 1 is obtained by blending of recycled textile fibres with bi-component fibres to form bulk wool, subse- quent thermal treatment and lamination with a polyester layer of needle-punched non-woven textile.

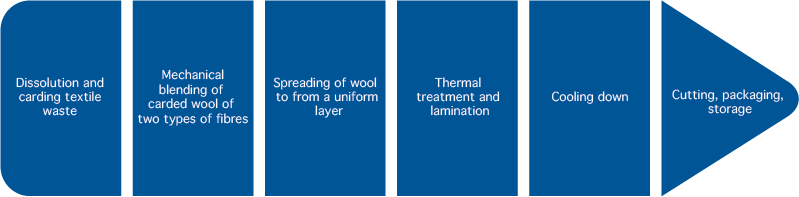

The main processes of TIPROT 1 manufacturing may be illustrated as follows:

The recycled textile fibres are about 75-90% by weight. The produced TIPROT has a thickness of about 50 mm. It is cut into rolls with a length of 10 m and a width of 60 cm, packed and labelled. The roll width and length may differ from the ones specified above. TIPROT 1 may be also produced in the form of plates/mattresses.

Essential characteristics

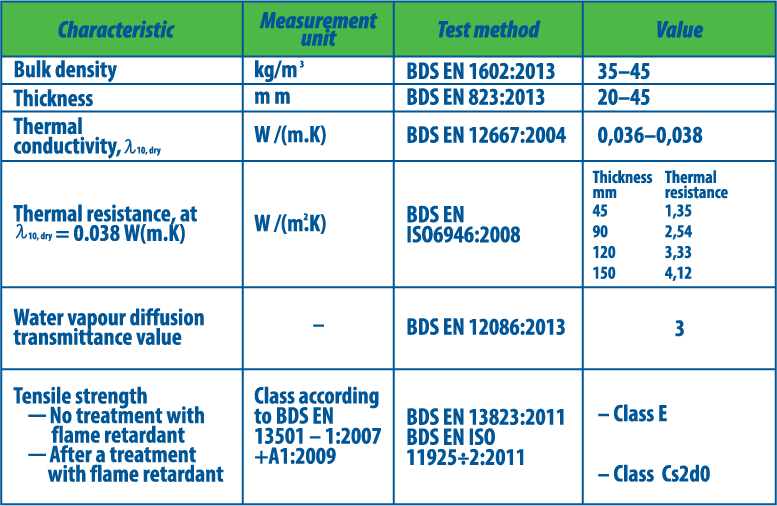

TIPROT features a fibrous structure whereby the space among fibres is occupied by air. Under stationary conditions, the air has very low ther- mal conductivity, i.e. it is a very good thermal insulator. The structure (having impact on air convection) of TIPROT and its bulk density, as well the fibres’ composition, thermal and physical properties, are of the greatest importance for the thermal Insulating capacity of TIPROT. TIPROT does not demonstrate a linear relationship between the bulk density and the thermal conductivity. The TIPROT compositional and structural parameters are not optimized so that low thermal conductivity at good construction properties may be ensured – Table 1.

The thermal conductivity value for each prototype is determined based on measurements of 3 (three) different test specimens taken at the beginning, in the middle and at the end of the production process of 500 sq.m of TIPROT 1 and TIPROT 2. The thermal conductivity is measured and recorded according to BDS EN 12 667 under the following conditions: average temperature +10оС and equilibrium moisture content in the specimens at a relative humidity of 50%.

The thermal conductivity of TIPROT is of the order of 0,036 – 0, 038W/(m.K) and characterizes it as a very efficient thermal Insulating material which is appropriate for thermal insulation of building envelope elements – Table 1.

Therefore, a thermal insulation consisting of 2 or 3 layers of TIPROT (single layer thickness of 45 mm) will achieve (and exceed) the reference values of thermal transmittance coefficient stipulated in Regulation No.7 dated 2004 on the energy efficiency of buildings for the different envelope ele-

ments. element to “breathe” – Table 1.

Among the attractive thermal properties of TIPROT, one should emphasize the high water vapour permeability which allows the insulated element to “breathe” – Table 1.

Fields of application

When the thermal insulation using TIPROT is envisaged for increasing the energy efficiency (for existing buildings) or for meeting the design requirements of new buildings, the most appropriate way (for buildings having low or medium relative humidity regime during use stage), is to install the thermal insulation inside of the envelope elements (walls, roofs and floors). This solution is particularly appropriate in buildings with seasonal occupancy due to the possibility for quick achievement of the desired climate parameters.

Placing the thermal insulation on the inner side has the following advantages:

- easy execution, including by not very qualified workers;

- possibility to apply so-called “dry construction systems”;

- lack of wet construction processes;

- no need of a scaffold;

- lack of the “patches” effect on the facades of multifamily building when only a part of the dwellings are heat-insulated;

- rapid execution;

- quicker heating of the premises in winter;

- better durability of thermal insulating materials, because theyare not exposed to atmospheric impacts, etc.

The disadvantages include a need of vapour barrier membrane to be installed in most of the cases, some reduction of the room efficient area, lack of protection for the building load-bearing structure from temperature impacts, impossibility to avoid certain thermal bridges, etc.

For overcoming these disadvantages, TIPROT may also be used in thermal insulation systems on the outside of the enclosing elements, but then, several measures should be taken in order to eliminate the risks caused by organic fibre rotting, mould and fungus growing, insects and rodents attacks. Such measuresinclude, for example, the

following:

- installation of a water-tight, but air-permeable membrane;

- need of a rigid (non-deformable) facade covering such as suspended facade and/or facade siding or front masonry/lining;

- different thermal insulating material at the plinth of building, etc. TIPROT may also be used as a stuffing layer in “sandwich” type panels when the requirements to their fire resistance are not too high, i.e. in this case, TIPROT

cannot be a substitute material for the mineral wool, but rather for the expanded PU foam used for this purpose.

TIPROT are appropriate for the following types of buildings:

- residential buildings – single-family and multifamily;

- shops;

- public buildings.

TIPROT may be installed on:

- masonry of ceramic bricks and blocks, calcium silicate bricks, concrete and cellular concrete blocks;

- reinforced concrete walls, provided that their moisture content is < 4%;

- timber linings and particles boards, provided that ventilation and weather protection are ensured;

- floors and roof slabs with a reinforced concrete structure (with a moisture content < 4%, if they are directly laid on the floor);

- roofs with a timber load-bearing structure provided with ventilation.

Rules on Healthy and Safe Work Conditions

TIPROT are safe during installation and use stage when certain common precautions are applied:

- TIPROT will be stored so as to be protected against damage, including against penetration of moisture;

- TIPROT will be cut using scissors or an even mat and a sharp knife with a dented blade. A saw should not be used and the roll should not be torn.

- Good natural ventilation will be provided at the work place.

- Safety goggles and possibly a breathing mask (in case of danger of allergic reaction) are recommended at use in closed rooms with insufficient ventilation.

- TIPROT are generally not an irritant for the hand skin, but in case of skin itching during the operation with TIPROT, the place shall not be scratched, but rinsed abundantly with cold water.

- The work place will be regularly cleaned so that there is no dust. Vacuum cleaner, rather than a broom, is recommended.

- Smoking and execution of process operations using heat or flame (for example, welding, gas-flame gluing and other similar) are not allowed in the vicinity of installed and/or stored TIPROT because there is a high risk of TIPROT inflammation.

Fire safety

When not treated with flame retardant, TIPROT are classified as class E (combustible products with significant contribution to a non-controlled combustion), but may be declared as products of class F (no testing is required) – combustible products with no definite reaction to fire performance.

To improve the fire resistance of walls, insulated with TIPROT, a suitable finish coat- ing on the inner side is recommended – for example by using plasterboard or fibreboard (their reaction to fire is class А1 or А2), single- or double-layer, depending on the fire resistance require- ments. Thus, TIPROT may be used in buildings with a degree of fire resistance IV and V.

When treated with flame retardants, such as those based on cyclic oligomer phos- phonate (up to 15% by weight), TIPROTs may be classified as class C (low-combustible products with restricted contribution to non-controlled combustion), which allows their use in buildings with higher requirements to the envelope fire-resistance.

Environmental performances

TIPROTs are thermal insulating products made of waste (instead of natural raw materials), by using an almost waste-free and low energy consumption (less than 0,8 kWh/m2) technology with which makes them a environmentally friendly product, characterised by very low consumption of resources and energy. At the same time, thanks to their excellent thermal insulation capability, TIPROTs contribute to increasing the whole energy efficiency of buildings.

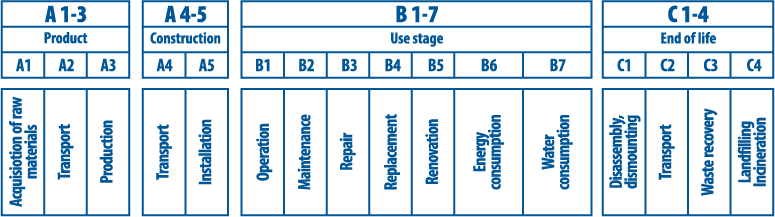

A detailed comparative life cycle analysis (LCA), in compliance with the requirements of BDS ЕN 15804 and BDS ISO 21930, was made, studying the environmental impact assessment of 10 varieties of TIPROT, differing by composition, properties and manifacturing process. The scope of LCA was “from cradle- to-grave“, i.e. LCA covers the whole product life cycle – from raw materials acquisition through its pro- duction, installation during construction, use stage in the building, and stage of building deconstruction, and at the end, the TIPROT waste treatment – figure 1. An evaluation is made whether the TIPROT waste is suitable for materials and/or energy recovery or it has to be landfilled.

As a “functional unit” (FU) for LCA, to which the in- formation about the effect of the different qualitative and quan- titative indicators is related, and for which the subsequent anal- yses were made, was chosen an unit of thermal resistance (R = 1 m2K/W), so that the inconvenience of products having different thickness and bulk density and therefore – different thermal in- sulating properties, may be overcome.

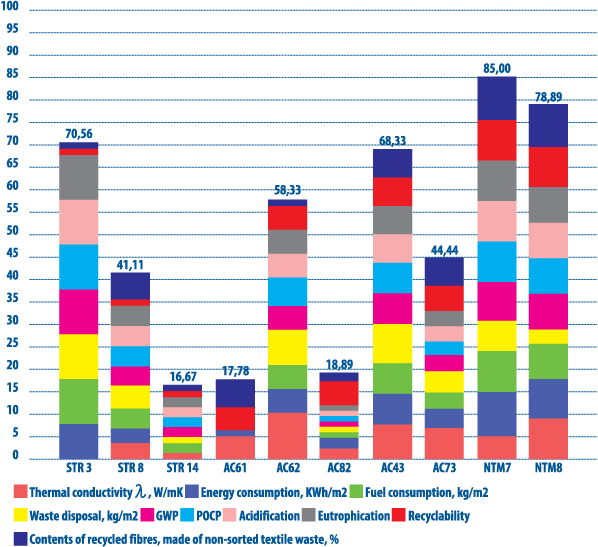

The thermal conductivity (recalculated as an equivalent thickness of TIPROT in cm, required for achieving R=1 m2.K/W), the content of fibres recycled from textile waste (%), the energy consumption (kWh/m2) and the TIPROT recyclability at the end of life (high, medium, low) are identified as evaluation criteria. Another direct energy criterion is related to the use of fuels and, therefore, to the greenhouse gas emissions (GWP, kg CO2 eqv./m2), eutrophication (kg PO4- eqv./m2), soil acidification (kg SO2-eqv./m2) and generation of photochemical ozone (POCP, kg C2H2-eqv./m2).

The effect of the different criteria, revealed by LCA, is shown in figure 2.

To good environmental performances the lack of hazard for people’s health and the environment during the con- struction and use stages of dwellings has to be added – if the recommended conditions for storage, installation and operation are respected, – TIPROTs do not release toxic gases, hazardous substance emissions, volatile organic compounds (VOC)k greenhouse gases or hazardous particles to the indoor or outdoor environment, there is no hazardous radiation either.

Due to the raw material peculiarities, in TIPROT there is some risk for mould growth of the most common strains living in the dwellings – Aspergillus niger, Aspergillus fumigates, Trichoderma viride and Penicillium sp. In case the moisture content of TIPROT is higher than the equilibrium value under normal conditions of use, the TIPROT dehumidification shall be provided (by ventilation and or drying) so that mould formation is avoided. The most efficient protection of TIPROT against these strains is provided by using substances called antimicrobials /biocides/ which take part in the chemical reaction in the cell membrane and thus, stop the microorganism metabolic process and lead to the destruction of the microorganisms. Some of the most polyvalent products which do not contain chlorine and are not hazardous for the environment and people’s health are the quaternary ammonium salts A small amount (less than 1% by weight) of production waste is generated during the manufactur- ing of TIPROT. That waste is mainly in the form of fibres and is to be managed as non-hazardous waste – it is gathered through air ducts and packed in bales. It has a high energy potential and may be used as a fuel (RDF). It will be forwarded to persons having a permission for execution of activity with code R1 (Utilization of waste mainly as fuel or another method for production of energy), as per art.35 of the Waste Management Act.

To minimise the construction waste during installation of TIPROT, the material has to be cut-out using appropriate means for cutting. This construction waste coming from of TIPROT may be collected separately under code 170604 (Insulating materials). In case of demolition/deconstruction of a building where TIPROT are used, they may be disassembled and may un- dergo a treatment for either reuse or recycling.